design coal roller mill

Coal mill overhauling works

· Grinding Roller Coal mill overhauling works. 1. Rollers Housing shaft bearing condition checking. 2. Rollers tyres replacement. 3. Classifier cone and body welding metalup where required. 4. Mill body inner liner plate or wear plate correction.

Coal pulverisation with vertical roller mills

· Coal pulveriser design. In general, coal pulverisers are designed to achieve the maximum rated capacity grinding a design coal with a grindability of 55 HGI and 812 per cent moisture and achieving a discharge fineness of 70 per cent passing a 200 mesh screen (74 micron) and per cent passing a 50 mesh screen.

coal mills design

Design Coal Mill design coal roller mill materiauxdelvaux be MPS vertical roller mill Coal mill gypsum mill clay mill etc Highest flexibility with constant product quality individually conceived suitable for a variety of appliions undergoing constant development with a number of more than 2800 mills sold the MPS vertical mill is .

Roller Mill Maintenance00

Roller mills are also more sensitive to instantaneous changes in the feed rate than are other pieces of process equipment. Feeding a roller mill directly from a screw conveyor or bucket elevator will cause surges in the feed rate that the roller mill "sees" instantaneously unless some damping system such as a surge hopper is used.

High Energy Coal Gangue Mill| Vertical Roller Mill

· Vertical roller mill equipment is not only a righthand assistant for solid waste residue projects such as coal gangue, slag, water slag and fly ash, but also an important equipment to promote the solid waste residue market to realize the value of recycling.

Design of Rolling Mills | Metallurgy

Design of Rolling Mills | Metallurgy. After reading this article you will learn about the design of rolling mills. A rolling mill includes one or more roller stands, a main drive motor, reducing gear, stand pinion, flywheel, and coupling gear between the units. The roll stand is the main part of the mill, where the rolling process is actually done.

coal roller mills

Coal Vertical Roller Mill Great Wall Corporation Chaeng Coal Vertical Roller Mill has simple process compact structure and it has less dust low noise high efficiency ...

Introduction to Rolling Process

2 Principles and Appliions of Metal Rolling (ii) Shape of the rolled product flat, sections or hollow sections rolling. (iii) Direction of rolling lengthwise, transverse, and skew rolling. (iv) Mode of rolling mill operation continuous (unidirectional), and reverse rolling, where direction of rotation of rolls are reversed. When two rolls of equal diameter and with axis lying in same ...

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER ...

factors and controller design for cement grinding are discussed in [37]. Figure1. Vertical roller mill for cement grinding [13]. VRM shown in Figure1 uses hydraulically hardpressed conical shape 24 rollers against the horizontal revolving grinding table. To enhance comminution, the axes of table and rollers do not traverse in the plane of the

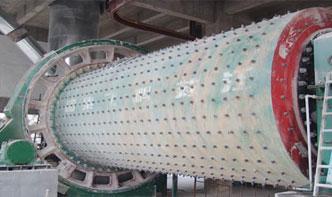

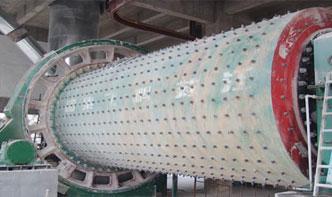

Ball Mill Design/Power Calculation

· The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type .

Vertical Roller Mill For Coal

· Vertical roller mill can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. Grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill.

Investigation on the CoalBased Direct Reduction of Mill ...

· The reduction study of the mill scale pellets has been carried out using the statistical design of experimental approach employing the response surface methodology. Under optimum conditions such as a temperature of 1246 °C, a time of h, and coaltomill scale ratio of, around 88–89% metallization is obtained.

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energyefficiency. Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range. Whether grinding raw coal, clinker, cement and/or slag, we ...

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL ...

Based on design criticality, past experience and previous failure ... milling stages if the materials need to be further reduced. ... mm. Screens (vibrating grizzly type or roller screens) provided upstream of the crushers screen out () 20 mm coal from the feed and

Coal Mill in Cement Plant | Vertical Roller Mill Air ...

Coal mill is also called coal pulverizer or coal grinder. It is a mechanical device used to grind raw coal into pulverized coal powders. The most used coal mills in cement plants are airswept ball mill and vertical roller mill.. At present, most cement plants use coal as the main fuel in the clinker production process.

Advanced Development of Pulverized Coal Firing Technologies

improved roller mills which have been developed by using our existing test furnaces and Computational Fluid Dynamics (CFD). We also describe a largescale coal combustion test facility. 2. Development of burners Social needs for coals to be used for pulverized coal fired boilers are moving from the bituminous coals toward the