hydraulic operation in vertical raw mill

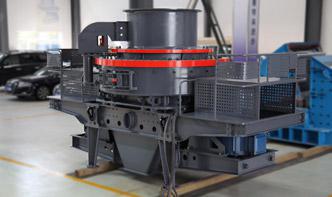

Vertical roller mill

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics. It is an energy efficient alternative for a ball mill. Overview. Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure ...

Vertical Mill Calculations | PDF | Mill (Grinding) | Nozzle

Optimization of Vertical Raw Mill Operation. Nael. Loesche Technical Seminar_apr15. Mob Morphling Kurustien. Mill (Grinding) Nozzle. Pressure. Mechanical Engineering. 411 Vertical Mills Operations_V10 . Sai Sricharan Reddy. Grinding Technologies. Joseph Leveque. RAW MILL VERTICAL ROLLER ManpreetSaran. Vertical Raw Mill Heat Balance .

Vertical Raw Mill Operation Guideline

Vertical Mills Operations Maintenance Training Fl. May 27, 2016 Where preblended wet materials are fed for dry ing in the raw mill, silos are unnecessary. Virtually all modern raw mills incorporate closed circuits with classifi ion in a cyclone or mechanical separator and return of coarse mater ial for regrinding (Figure 3). Ball mill operation is described in detail .

vertical cement mill in operation

Hydraulic system vertical roller mill operation. Mar 25,, The hydraulic system of vertical mill is an important system, the main function of the hydraulic system is to break the grinding roller, which is. live chat; Patent US. Feb 27,, Cement clinker grinding method using vertical roller mill and apparatus, Particularly, regarding the ...

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energyefficiency. Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range. Whether grinding raw coal, clinker, cement and/or slag, we ...

what is the Max. Nitrogen gas pressure in accumulator for ...

· Re: what is the Max. Nitrogen gas pressure in accumulator for vertical roller mill hydraulic cylinder ENGRs sir if we exceed or keep low this nitrogen pressure in accumulator then wat will hapend. we have loesche mill capacity 490t/h and our nitrogen pressure is about 40bar normally we operate mill with grinding pressure upto 96bar. Reply

MACHINING OPERATIONS AND MACHINE TOOLS

MACHINING OPERATIONS AND MACHINE TOOLS. 1. Turning and Related Operations. 2. Drilling and Related Operations. 3. Milling. 4. Machining Turning Centers . 5. Other Machining Operations. 6. Shape, Tolerance and Surface Finish. 7. Machinability. 8. Selection of Cutting Conditions. 9. Product Design Consideration. 2. d. f. D. o. D. f. L. 1. Turning Related .

Vertical Raw Mill Operation

Vertical Raw Mill Operation . MVR vertical roller mill with planetary Gebr. Pfeiffer. Introduction Vertical raw mill is a type of industrial equipment used to crush or grind materials into small roller mills are widely used in the concrete and mining fields, and are also used to process gypsum.

Pulverizers 101: Part I

· Pulverizers prepare raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to .

Operation Of The Vertical Roller Mill

Operation Of The Vertical Roller Mill. As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc. we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan.

Operation Of Vertical Raw Mill Cement Industry

Vertical raw mill and cement mill operation – Coal processing Cement Manufacturing Vertical Roller Mills for Finish Figure mill in operation at a cement plant. easy operation and maintenance, is. Read More Vertical Roller Mill Cement Industry News From Global Cement . Mar 13, 2019 The order was for two vertical roller mills (VRM) one type LM for grinding .

(PDF) Performance Evaluation of Vertical Roller Mill in ...

mill operation is crucial for control the s ystem and . improvement of the efficiency. Based on this, sampling . studies were performed at vertical roller mill of ESCH . Cement Plant, which is ...

Vertical Roller Mill Operation In Cement Industry

Vertical roller mill in cement industry vertical roller mills especially those common for grinding of cement raw materials typically employ a hydraulicpneumatic system to apply a grinding force to the material bed during operation these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting. Details. Kolkata vertical roller mill operation cement ...

Industrial Solutions quadropol QMR²

example, roller speed, roller vibration and hydraulic pressure. Operating data may also be evaluated via remote access. Flexibility and ease of maintenance are the outstanding features of the quadropol ® QMR² roller mill for raw material. This is ensured by a proven drive concept and a standardised design. 4 . The perfect configuration The gas distribution in the quadropol ® .

Vertical roller mill for raw Appliion p rocess materials

Vertical Raw Mill EP Raw Mill EP fan 69 4 Item Pregrinding equipment for raw material grinding process Appliion process Raw material process Background Recently, the vertical roller mill having great grinding performance is widely applied to the raw material grinding process. However, tube mill, which has about 30% poor grinding performance as power .