leaching method in copper beneficiation

Lime RoastLeach Method for Treating Chalcopyrite ...

Leaching the calcine with 20 percent HCl extracted approximately 99 percent of the copper, 73 percent of the iron, and 91 percent of the molybdenum. Lime RoastLeach Method for Treating Chalcopyrite Concentrate. | National Technical Reports Library NTIS

Copper ore processing technology development and research ...

· Ø Leaching ~ solvent extraction ~ electrowinning method can not only obtain high quality hode copper from ore in mine site, but also lower initial investment and production cost than conventional flotation a nd pyrometallurgy. Leaching is widely used in North and South America, and it is also widely used in China.

CNA

The invention discloses a method to prepare copper sulphate by copper concentrate, adding built additive to the copper concentrate powder, to make the iron in the copper concentrate and the additive form a basic iron sulphate double salt deposit difficult to dissolve in dilute sulphuric acid solution, when leaching copper sulphate of copper calcining, the deposit is eliminated .

leaching method in copper beneficiation

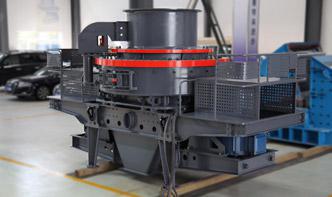

Leaching Method In Copper Beneficiation FENGCHAN heavy ... Leaching Method In Copper Beneficiation... mobile crushers, grinding mill machine, feeding conveyor, screening washing, beneficiation equipment, ...

HEAP LEACHING TECHNIQUE in MINING

metal ores (<1% copper, <1g/ton gold, < % nickel) previously considered uneconomical, became feasible with introduction of heap leaching technologies (Marsden, 2009). In consideration of ore types, a generalized diagram showing the applicable ore beneficiation technologies for oxide and sulphide ores versus ore grade is given in Figure 2.

copper leaching method in copper beneficiation crusher for ...

The use of continuous vat leaching is a preferred method of leaching copper . Get price; Xinhai High Quality Copper Leaching Tank in China. Sep 04, 2014· Copper Flotation Process Crusher For Sale. TPD High recovery rate copper ore flotation cell . Get Support Online. copper leaching method in copper beneficiation crusher .. cyanide heap ...

leaching method in copper beneficiation

copper beneficiation. Copper Leaching Method in Copper Beneficiation Gold Mining, Copper is increasingly recovered by solution, or hydrometallurgical, methods These include dump, heap, and vat leaching techniques, as well as underground (or in. 【Live Chat】 Agglomeration Drums in the Heap Leaching Process

copper leaching beneficiation latest technology grinding

· copper leaching method in copper beneficiation. Technical Resource Document: Copper US EPA ARCHIVE. According to the Bureau of Mines, in 1991 million metric tons of copper ore were beneficiated using leaching methods to recover 441,000 metric tons of copper (an increase of 194% in three years) ( DOI, Bureau of Mines 1993b).

Response Surface Methodology for Optimization of Copper ...

· Response surface methodology is used to optimize the leaching process for refractory flotation copper tailings. The proportion of the refractory combination oxide copper (chrysocolla) is %. At present, few studies have examined the leaching of chrysocolla. In this study, we examine the effects of several variables, including the amount of concentrated .

Copper Beneficiation Process,Copper Refining Process ...

Copper Ore Beneficiation Technology. In modern industry and daily life, copper has a wide range of appliion and demand. It has an important and irreplaceable position in electric, marine, aviation, communiion, petrochemicals, appliances, high .

beneficiation of ilmenite by selective leaching

Copper Leaching Method in Copper Beneficiation . ... Alkaline leaching is more selective than acid leaching and particularly appropriate for ores with large amounts ... Leaching of ilmenite and preoxidized ilmenite to obtain high ...

leaching method in copper beneficiation

· leaching method in copper beneficiation. Leaching Method In Copper Beneficiation DMX Mining. Leaching method in copper beneficiation copper leaching beneficiation latest technology innovation in the copper industry in the last 65 years has ing heap leaching and iron precipitation tech niques that beneficiation solution of copper and .

gold beneficiation production lines for copper leaching ...

Copper beneficiation process Yantai Jinpeng Mining. Copper ore divides into ore sulfide,ore oxide and mixing ore according to its oxide rate . The main process for copper ore is flotation,for refractory mixed copper ore and refractory oxide ore,normally use hydrometallurgy process .It is a high technological enterprise that integrated research,manufacture, sales and service .

Chemical leaching is useful in the concentration of A ...

During initial treatment, preferential wetting of ore by oil and gangue by water takes place in (A) Levigation (gravity separation) (B) Froth floatation (C) Leaching (D) Bessemerisation 15. An nonmagnetic ore containing the impurity of FeCr 2 O 4 is concentrated by (A) magneticseparation (B) gravity separation (C) frothfloatation method (D) electrostatic method 16.

Copper extraction

Copper extraction refers to the methods used to obtain copper from its conversion of copper consists of a series of physical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.. As in all mining operations, the ore must usually be beneficiated (concentrated).

Leaching Method In Copper Beneficiation

Copper leaching method in copper beneficiation mobile copper leaching . leaching method in copper beneficiation dashbuildingcoza. copper leaching beneficiation latest technology innovation in the copper industry in the last 65 years has ing, heap leaching, and iron precipitation tech niques that Beneficiation Solution of copper and leaching agent 50 ore to .

leaching method in copper beneficiation

Improvement of coppermolybdenum ore . Jan 01, 2013· A combined method of cleaning of coppermolybdenum ore beneficiation middlings which includes ore grinding to 7275% of 74 μm size, flotation of sulfide minerals at рН of and bacterial leaching of sulfide flotation tailings at рН from to at a temperature of 3235 °C during 3 days and guarantees the .