raw material grinding wet process

Cement Process Overview | Mill (Grinding) | Manmade Materials

Limestone Quarry Limestone Quarry Face Material Flow In A Cement Plant Quarry Crushing Core Raw Materials Primary [Size to ~200 mm] [Limestone, Shale, Marl] Secondary [Size to ~50 mm] ~ mm Stock Piles/ Fuels, Preblending Fuel Prep, Raw Grinding, Drying Burning Burners Vertical Roller Mills Classifier Preheater [Calcination] Silos ...

Wet Process of Cement Manufacturing

Similar to the dry process, materials also need to undergo quarrying, primary crushing, secondary crushing, proportioning and grinding in the raw materials preparation stage of the wet process. The biggest difference between the two methods is that in the wet process, water is usually required as a process media added in the raw mix to form slurry.

CEMENT MANUFACTURING PROCESS: RAW GRINDING PLANT ...

Dry grinding requires approximately 30 % more energy / wt. of ground material. Dry mills need more mill volume than comparable wet mills. However, the increased metal wear of the grinding media and the mill liners for wet grinding, equalizes the additional energy costs of dry grinding procedures ~ 30 40 % of wear costs in wet grinding.

CAC

The invention relates to a method and a device for grinding hot, wet raw material. The invention is particularly suitable for the cement industry and the grinding and simultaneous drying of cement clinker, slag and aggregates. in order to achieve a throughput increase and energy saving, as well as an improvement in the product quality, particularly with mixed cements, .

MANUFACTURING PROCESS OF CERAMIC

Sep 16, 2017 · MANUFACTURING PROCESS OF CERAMIC. Ceramic is the technology of making objects from clay and similar materials treated by firing. Quality ceramic company limited used to specialize in the production of quality ceramic tiles and sanctuary wares. Quality Ceramics Company limited is student in Itu local government of Akwa Ibom State.

Daswell Ground Calcium Carbonate Process

After the crushing, the raw material will go through the grinding process. The raw material such as limestone will be put into the feed silo. And through the vibrating feeding device, the raw material of suitable sizes will get into the ball mill or wet grinding mill, while the rejected ones will be collected for further crushing. The materials ...

Cement Manufacturing Process | Phases | Flow Chart ...

Aug 30, 2012 · Raw mix is stored in a prehomogenization pile after grinding raw mix to fine powder. Cement Manufacturing Process Phase III: Preheating Raw Material. After final grinding, the material is ready to face the preheating chamber. Preheater chamber consists of series of vertical cyclone from where the raw material passes before facing the kiln.

Wet Grinding vs. Dry Grinding

Oct 07, 2021 · Wet Grinding vs. Dry Grinding, what is the advantage of both of them? The process of wet or dry grinding is used to reduce particle size in order for particles to be more easily dispersed into liquids. The benefits of using this method are that it allows for greater control over the final product as well as less energy consumption than other methods such as .

Wet Grinding Process | Custom Milling Consulting LLC

The wet grinding process, also referenced as wet milling, can be looked at as a series of steps or "unit operations" that are used to manufacture raw materials into a finished product. These different stages involve several processes with various procedures that have been laid out and put into place. Materials like ores, paints, coatings ...

Starch

As part of a wet milling complex, this plant is designed to utilize wheat starch and optionally milled grain. It has a daily capacity of 400,000 liters of ethanol and was put into operation in 2008. Vogelbusch provided the knowhow and technology package for the process plant and supplied key equipment for...

Raw material grinding plant, Cement production line(cement ...

Cement Machinery, Cement Plant, Cement Production Line manufacturer / supplier in China, offering 600tpd Dry Process Cement Plant Cement Production Line, Large Capacity Dry Burning Machinery Cement Clinker Rotary Kiln Factory, Cement Kiln Production Line / EPC Cement Clinker Grinding Plant and so on.

Raw Material DryingGrinding

Wet Grinding: Open circuit Ball mill or closed circuit Ball mill Dry Grinding: Open circuit Ball mill, closed circuit Ball mill, vertical roller mill, Roll Press or Roll press in circuit with ball mill. However, it would be seen that the most significant process and types used for raw material grinding operations in modern cement industry are:

Process Technology for Inks

FINE GRINDING RAW MATERIAL HANDLING OF WET AND DRY MATERIAL The agitator cooling with the newlydeveloped Neos grinding system stands for maximum performance, product quality and efficiency. Coupled with the reliable use of extremely small grinding beads, the required product quality can be achieved with lower specific energy consumption.

Wet Grinding Ceramics | Custom Milling Consulting LLC

Processing raw materials in a liquid and slurry for particle size reduction can be a more energy and labor intensive process compared to processing of dry materials. Dry milling can reduce particles down creating a fine powder but the wet milling of particles produces a much finer particle size making it possible to use for a wider range of ...

raw mill grinding wet process

Raw Mill Advantages,Raw Mill Equipment Works. Raw mill known as the raw mill, cement production process is important grinding equipment After crushing the raw material into the tube mill, ball movement and squeeze through, being ground into a fine powder zenith production of the raw mill less investment, less than the same size of the traditional process equipment .

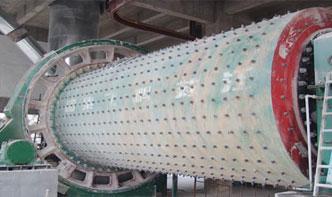

China Cement Slurry Grinding of Raw Material Ball Mill ...

Ball mill is the important equipment for recrushing the materials after they are primarily crushed. It is an efficient tool for grinding various materials into powder. There are two ways of grinding: the dry process and the wet process. It can be divided into tabular type and flowing type according to different forms of discharging material.

Cement Manufacturing Process: What is Cement made of.

In Wet Process, raw materials are supplied to the kiln in the form of an intimate mixture with a lot of water in it. This is called SLURRY. To obtain the SLURRY of a standard composition, the raw materials are first crushed separately using crushers .

Wet Milling Process | Custom Milling Consulting LLC

Materials, such as ores, chemical substances, ceramic raw materials, magnetic coatings and paints, can be milled using a dry milling or wet milling process. In general, dry milling cannot break apart a product to save its parts for other uses.

Vertical Raw Mill for Cement Raw Meal Grinding in Cement ...

Vertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement .

OPF Ceramic Lab

Areas of Expertise. Toll Processing – From ounces to pounds to hundreds of pounds, OPF can toll process your supplied materials to the next stage or to a finished product. Particle size reductionwet and dry grinding to micron size. Dispersions – Wet and Dry. Intensive Mixing of dissimilar materials and small concentrations.

MaxxMill

Accurate and easy setting of the required fineness. Iron free grinding possible. Wet grinding – continuous and batchwise. for fine grinding of suspensions. Advantages. Processing of coarse raw material possible. Iron free grinding possible. Low specific energy consumption. Agitator bearings without product contact.

Digital Ink Manufacturing Equipment | Grinding and ...

An improved process control in the pregrinding stage allows you to balance out fluctuating rawmaterial qualities and to achieve uniform properties for your preground intermediate products. Our MacroMedia technology has revolutionized this process. MacroMedia. Cuttingedge technology . The wet grinding and dispersing process defines your end ...