vertical milling process

MILLING MACHINE OPERATIONS

or vertical to indie the axis of the milling machine spindle. These machines are also classified as kneetype, ramtype, manufacturing or bedtype, and planertype milling machines. Most machines have selfcontained electric drive motors, coolant systems, variable spindle speeds, and .

SERIES I MILLING MACHINES

safeguarding should be used on milling machines to the greatest extent practicable. This booklet provides basic information for the installation and use of the general purpose safeguard. It also contains the names of several manufacturers of other types of point of operation safeguarding for vertical milling machines.

How does milling machine work

27/02/2018 · The milling head is mounted on a trolley driven by a connecting rodcrank system allowing longitudinal movement with a straight motion. Universal milling machines; Universal milling machines are those that combine the functions of horizontal and vertical milling machines. In universal milling machines the workpiece table can also be rotary.

Report on milling machine

20/09/2017 · *Milling machine: is a power operated machine tool in which work piece mounted on a moving table is machined to various shapes when moved under a show revolving serrated cutter. Milling is the process of machining flat, curved, or Irregular surfaces by feeding the work piece against a rotating cutter containing a number of cutting edges.

VERTICAL MILLING MACHINE OPERATION

milling, drilling and boring. It would be extremely difficult to determine whether a vertical mill or a lathe would be the most valuable machine in a shop. Theoretically, most vertical mills are capable of reproducing themselves with standard milling .

Toolholders for vertical milling | john f's workshop

Vertical milling cutters can be held by a toolholder that is just a hole in the chuck. The cutter just fits into this hole. The cutter is held in place by a screw that fits a recess on the side of the cutter. This is the side lock chuck. One side lock chuck will only fit cutters of one diameter. It the cutter has a flat on it, it will not ...

Types of Milling Cutters Used in Machining Process

These types of milling cutters have the cutting teeth on the both sides. We use end mill more in the vertical milling processes. High speed steel or the cemented carbide are used to create end mills. High speed steel is also called as HS or HSS. The high speed steel doesn't loose its hardness when the temperature increases.

Milling Equations

Milling Equations Machining Time : Peripheral Milling T m = L + A f r T m = Machining Time (Min.) L = Length of Cut A = Approach Distance f r = Feed Rate (Dist./ Min.) Machining Time : Face Milling T m = f r L + A + O T m = Machining Time (Min.) L = Length of Cut A = Approach Distance O = Cutter Run Out Distance f r = Feed Rate (Dist./ Min.) 4

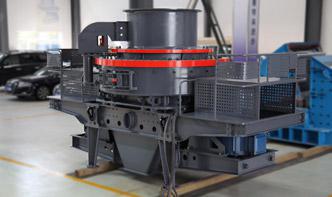

Vertical Milling Machine | MachineMfg

The vertical milling head can be adjusted by ±45° in the vertical plane for smooth and reverse rotation, which expands the machining range of the machine. The main shaft bearing is a tapered roller bearing with strong bearing capacity, and the main shaft adopts energy consumption braking, and the braking torque is large, stopping quickly and ...

Vertical Milling Machine

Milling machines use complex, multitooth rotary cutters to make compound cuts. There are four standard types of milling machines. They are the bed type, column and knee, horizontal, and vertical milling machines. This sheet describes the procedure for using a vertical milling machine to drill a hole and slot to make a key way.

What is Milling Machine? Parts, Operation, Diagram ...

2. Side Milling. In this process, the flat vertical surfaces produce at the side of a workpiece. This process is done with a side milling cutter. Side milling is the operation of producing a flat vertical surface on the side of a workpiece by using a side milling cutter. The depth of cut is set by rotating the vertical feed screw of the table. 3.

How Vertical Milling Machines Lead to Improved and Diverse ...

21/05/2019 · CNC vertical milling uses automated processes to control specialized rotary cutting tools that remove material from a workpiece's surface. Manufacturers use CNC vertical milling to both form a workpiece and to create detailing on its surface. It's most often used to cut small holes and notches and to create threedimensional products.

Vertical Milling Machine

Vertical Milling Machine This study guide will cover the major working parts, functions, and machining techniques that can be found/used on most vertical milling machines. This study guide has been designed to directly represent the questions that will be found on the open book written assessment and as an aid for the handson usability assessment.

Milling Process, Defects, Equipment

Manual vertical milling machine. The above components of the milling machine can be oriented either vertically or horizontally, creating two very distinct forms of milling machine. A horizontal milling machine uses a cutter that is mounted on a horizontal shaft, called an .

Advantages And Disadvantages Of Milling Machine |

Milling is most common process nowadays used in industries and in workshops for machining of different materials to precise sizes and shapes. A milling machine can be a Horizontal or Vertical which depends over the orientation of the spindle. In the milling machines the movement of workpiece and the milling cutter can be controlled manually ...

Horizontal Milling, Vertical Milling

08/01/2010 · A milling machine is basically used for shaping, routing, boring, and drilling metals and other solid materials. Generally there are two egories of the milling machine which include the vertical type and the horizontal type. In order to optimize the capacity of the milling machine, it is essential to identify the appropriate milling machine type for specific tasks.

Milling machine(husain)

03/10/2015 · ARBORS Fig : Mounting a milling cutter on an arbor for use on a horizontal milling machine. 21. (B) VERTICAL MILLING MACHINE Spindle is vertical or perpendicular to the work table. It has all the movements of the table for proper setting and feeding the work. Spindle head may be swiveled at an angle, permitting the milling cutter mounted on the ...

The Difference between a Horizontal and Vertical Milling ...

30/10/2019 · In addition, most vertical mills can only mount one cutting head (spindle) at a time. Fortunately, there's another type of mill which addresses some of those difficulties. Uses of a Horizontal Milling Machine. At first glance, horizontal and vertical milling machines look very similar, or at least they can look quite similar.

CONVENTIONAL MACHINING PROCESSES AND MACHINE .

Another type of knee and column milling machine possible is the verticalaxis type. Most of the construction is very is very similar to the horizontalaxis type except the spindle type and loion. The spindle is loed in the vertical direction and is suitable for using the shankmounted milling cutter such as end mills.

Vertical roller mill for raw Appliion p rocess materials

vertical roller mill Appliion process Raw material process Background In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purpose.

Process Parametric Optimization of CNC Vertical Milling ...

IOSR Journal of Mechanical and Civil Engineering (IOSRJMCE) eISSN:,pISSN: X, Volume 6, Issue 5 (May. Jun. 2013), PP 3442 Process Parametric Optimization of CNC Vertical Milling Machine Using Taguchi Technique in Varying Condition Piyush pandey*, Prabhat kumar sinha, Vijay kumar, Manas tiwari Mechanical .

Wet Milling Process | Custom Milling Consulting LLC

Wet milling, also called wet media milling, is a process in which particles are dispersed in a liquid by shearing, by impact or crushing, or by attrition. A mill is charged with media (small beads or spheres) and activated by a highspeed agitator shaft to separate the individual particles.