ball milling teqnique

Difference Between Sag Mill vs Ball Mill

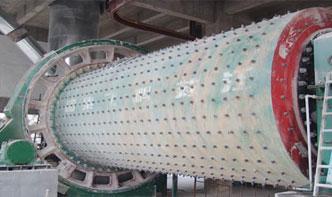

Oct 12, 2017 · BALL MILL. 1. SAG mill is the primary tool for grinding. SAG mill is used before the other mills. Ball mill is a secondary, and it is used after the SAG mill. 2. SAG mill breaks the raw material into pieces for the further grinding. Ball mill is used to grind the pieces of raw material into. powderlike structures.

Playing ball with the Haber–Bosch process

Dec 23, 2020 · The fact that the industrial Haber–Bosch synthesis loop for N 2 + 3H 2 = 2NH 3 is exothermic also poses challenges to the scaleup of the mechanochemical pathway in terms of the associated thermodynamics. This means not only the thermal management would be a challenge to the ballmilling ammonia synthesis process, namely, reactor cooling is ...

Structural and Physicochemical Characterization of ...

Aug 12, 2016 · Ball milling processes involve a powder mixture placed in the mill and subjected to highenergy impact from the balls. The process has grown from inducing metallic alloying to become an alternative technique for producing metallic and ceramic powder particles in the solid state by inducing specific chemical reactions.

The history and processes of milling

Jan 25, 2011 · Stone milling was the only way to make grain into flour for millennia. Farmers would sell their grain to the mill in their area and the mill would process that grain and sell it to bakers. Stone mills were powered by water or wind to grind the grain between two large stones. Stone mills were common throughout Europe and they were excellent for ...

Effect of Ball Milling on the Tensile Properties of ...

May 14, 2004 · Combining ball milling with stir casting in the synthesis of nanocomposites is found effective in increasing the strength and ductility of the nanocomposites. In the first step, .

Synthesis and characterization of nanodiamondszinc oxide ...

The doping is performed by ball milling technique. The effects of NDs contents upon the microstructure and subsequently, upon the characteristics of ZnO has been investigated in .

Is Ball Milling An Innovative Technique For the Production ...

The process of mechanical alloying using ball milling transfers mechanical energy to reactants in powder form, causing the particle size of the reactant powders to be reduced until defects in .

ZnO nanoparticles obtained by ball milling technique ...

The ZnO nanoparticles were obtained by ball milling of commercial grade ZnO powder at 250 rpm for 20 h and studied their structural, microstructure, optical and photoalytic properties. Due to ball milling significant decrease in lattice parameters and average crystalline size is noticed for the asmilled ZnO nano powder. The HRSEM images of the asmilled .

Highenergy ball milling technique for ZnO nanoparticles ...

Apr 29, 2011 · Nanoparticles of zinc oxide (ZnO) are increasingly recognized for their utility in biological appliions. In this study, the highenergy ball milling (HEBM) technique was .

Grinding, milling, crushing

A whole range of grinding/milling techniques and equipment are available for appliion with different types of food. Grinding/milling can be carried out dry or wet. In wet grinding/milling smaller particle sizes can be attained. Often dry grinding (milling) is combined with sieving or air classifiion, this results in particle size fractions.

ball milling technique instrument

Ball milling of the two overgranulated batches reduced the particle size, resulting in a smaller particle size than the starting material. Volume mean diameter by laser diffraction was 41 and .

Materials | Free FullText | Cellulose Nanofibrils as a ...

Mar 18, 2022 · Nanosized zeolite Y is used in various appliions from alysis in petroleum refining to nanofillers in water treatment membranes. Ball milling is a potential and fast technique to decrease the particle size of zeolite Y to the nano range. However, this technique is associated with a significant loss of crystallinity. Therefore, in this study, we investigate the .

End Mills. The Essential Beginners Guide.

Ball Nose End Mills. Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece, meaning less work for you as the piece won't need to be finished any further. They are used for contour milling, shallow slotting, pocketing and contouring appliions.

PREDICTION OF PARTICLE SIZE DISTRIBUTION OF A BALL MILL ...

Dec 02, 2021 · In the mining industry, it is important to minimize the wastage of raw materials while achieving the desired particle size distribution by grinding the original input mix. To date, the procedure is performed manually, and there is no such control mechanism for grinding that reduces wastage to achieve the desired output, resulting in the loss of material.

ball milling technique instrument

Ball milling of the two overgranulated batches reduced the particle size, resulting in a smaller particle size than the starting material. Volume mean diameter by laser diffraction was 41 and 34 μm for the two ball milled batches with and without HPC, geometric mean particle size by mesh analysis was 54 and 89 μm for the two batches, respectively.

Synthesis and characterization of nanodiamondszinc oxide ...

The doping is performed by ball milling technique. The effects of NDs contents upon the microstructure and subsequently, upon the characteristics of ZnO has been investigated in detail. The synthesis of the ND/ZnO nanocomposites are monitored by using different characterization techniques including IR spectroscopy, powder Xrays diffraction ...